For manufacturers who need to keep delivering — without downtime.

For producers who must perform — and keep operations running.

Delivery reliability decides.

But 90% of all delivery problems arise from unplanned machine downtimes.

Transaction-Network provides transparency on downtimes, automates maintenance processes and ensures predictable machine availability, for maximum delivery reliability.

Reliability builds trust. When production keeps running, you win markets, outperform competitors, and earn the confidence of customers who count on dependable partners.

We work with decision-makers responsible for production, delivery capability, and the next level of industrial collaboration.

Reduced downtime. Increased availability.

“Transaction-Network adds structure to our service and intelligence to our data.” Thanks to AI-based predictions, we reduce downtimes, ensure spare part availability, and plan our machine operating times much more efficiently.

We no longer make decisions based on intuition, but on data and system. For us, this is the way to genuinely predictable machine operations and improved delivery reliability.

This is how we achieve truly plannable machine performance and higher delivery dependability.

Leon Jerg, Managing Director

Jermi Käsewerk GmbH

How can we deliver if the machines aren’t running?

Downtimes jeopardize delivery capability – daily, unplanned, uncoordinated.

And what if service processes finally ran seamlessly, downtimes became visible early, and machine availability became predictable?

Problem 1

No one knows who needs to do what, or by when.

Situation:

A machine breaks down on Monday morning — the spare part is available, but no one has coordinated the service appointment. The manufacturer is waiting for feedback, and the operator doesn’t know who is responsible.

Impact:

Two days of production downtime because information and responsibilities are not transparent. The delivery date for a major order is at risk, and sales must placate the customer.

Problem 2

Every machine operates differently, and every service process runs differently.

Situation:

The plant operates seven machines from five OEMs — each with a different maintenance system, different contacts, and its own tools.

Impact:

The operator loses time every day due to manual tracking, Excel sheets, and incomplete documentation. Service planning is reactive instead of proactive. Mistakes happen because no one has the full overview.

Problem 3

Maintenance was postponed, and now everything has come to a standstill.

Situation:

“Maintenance of the critical machine was postponed internally because ‘everything’s still running.’ Two weeks later, it broke down unexpectedly — right in the peak of the delivery period.”

Impact:

The production plan falls apart, night shifts are required, and penalty fees are at risk. The operator’s confidence in their own planning erodes — and customers begin to doubt the company’s delivery reliability.

Economic Impact

Strategic Impact

Operative Impact

In summary

If you don’t take action, you pay every day — in money, time, customer trust, and strategic competitiveness.

You keep improvising while others are already automating.

We work with decision-makers responsible for production, delivery capability, and the next level of industrial collaboration.

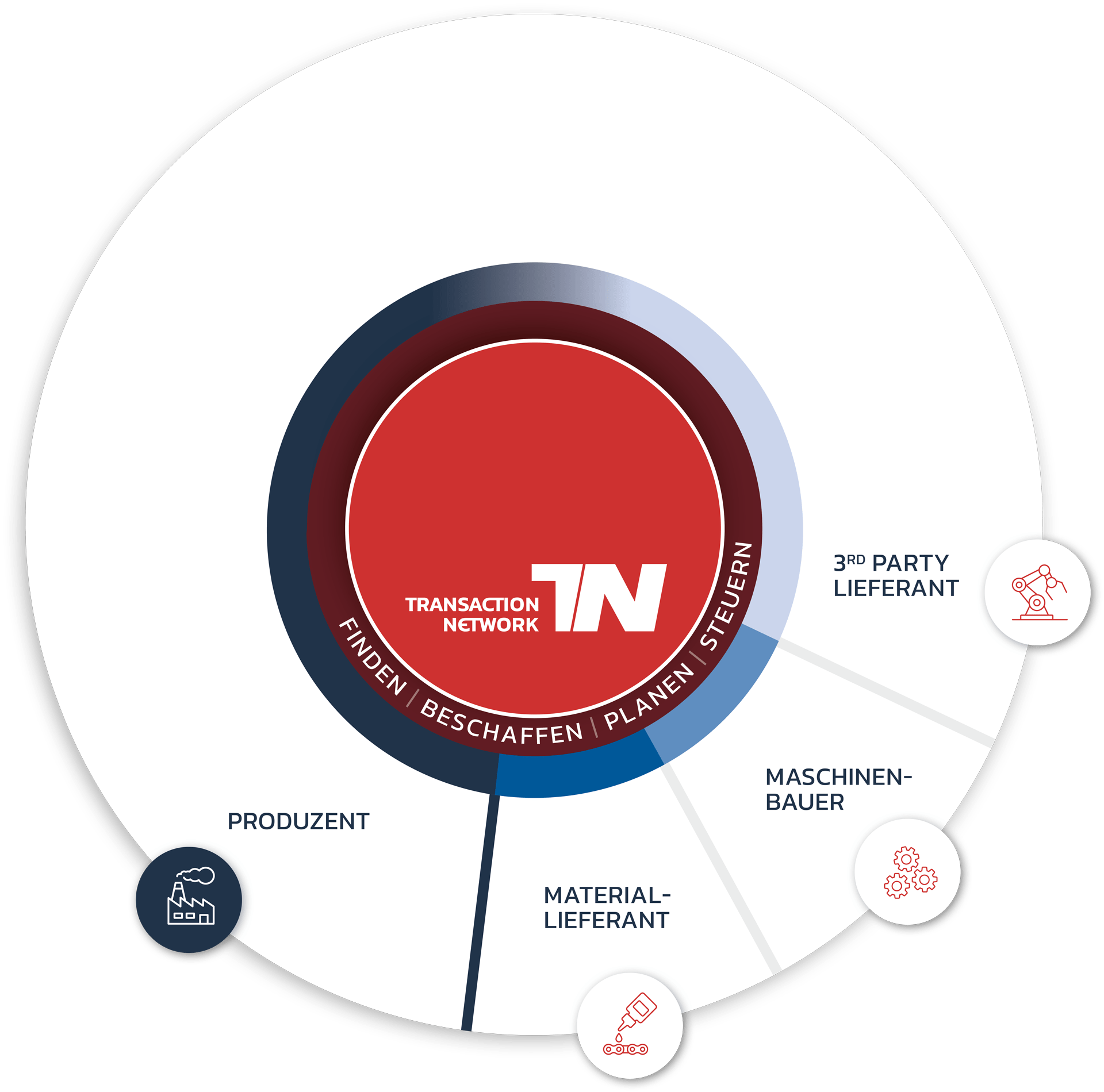

We create predictable machine availability through a digital, manufacturer-independent service ecosystem that connects operators and machine builders in a structured way.

Transaction-Network makes downtime visible, automates service processes across the entire machine, and enables a new form of industrial collaboration — transparent, reliable, and scalable.

This helps you reduce unplanned downtime, ensure delivery reliability, and strengthen your customers’ trust.

Digital Machine File & Real-Time Transparency:

All assets, all incidents, all responsibilities — consolidated on a single platform.

Service Automation with AI Agent & Maintenance Scheduler:

From intelligent fault detection to structured execution — fully digitalized.

Coordinated Collaboration with OEMs & Third-Party Providers:

Manufacturers, suppliers, and service partners are seamlessly integrated — ensuring smooth handling of spare parts, maintenance operations, and service tasks.

Open Ecosystem for Machine Service:

Can be expanded to include component manufacturers, material suppliers, service providers, and digital partners — enabling scalable, interoperable collaboration across the entire machine lifecycle.

Deliver — just as promised.

Because your machines keep running — and your service finally runs smoothly.

Use Case 1

Downtime caused by a missed maintenance schedule

Starting Situation:

A critical processing machine breaks down due to an overdue oil change. The maintenance requirement was known, but the appointment was overlooked amid the busy day-to-day operations.

Solution with Transaction-Network:

The digital maintenance scheduler automatically sends reminders, involves the OEM directly, and creates a planned service ticket — including spare part requirements and a detailed process plan.

Result:

No downtime — because maintenance was carried out on time, in a structured way, and with clear accountability. The production schedule remains stable, and delivery reliability is ensured.

Use Case 2

Full Traceability for Machine Downtime

Starting Situation:

A plant manager is faced with a delivery delay. The cause was a production stoppage — but no one can say exactly when it happened, why, or whether the OEM had been informed.

Solution with Transaction Network:

All machine incidents, downtimes, service requests, and responses are automatically documented — with timestamps, status, and involved parties. Everything is stored in the digital machine file.

Result:

Complete traceability — both internally and externally. The manufacturer can demonstrate to customers and management that operations are well-organized, proactive, and structured.

Use Case 3

Spare Parts Supply Stalls — Delivery at Risk

Starting Situation:

A gearbox failure is imminent, but the manual spare parts order is placed too late. The OEM takes too long to respond to inquiries, and production comes to a halt.

Solution with Transaction-Network:

Through the integrated online shop, the spare part is requested directly from within the maintenance process. Communication between OEM, operator, and logistics is digitally synchronized.

Result:

Smooth supply of the correct part — no information loss, no delays. The machine is back up and running the next day, and the delivery deadline is met.

Transaction-Network is the digital service ecosystem that brings together manufacturers and producers on one platform — ensuring minimal downtime and maximum delivery performance.

We’re not another software tool, but the operational backbone for predictable service — practical, interoperable, and effective from day one.

Our impact is clear: avoid downtime, reduce costs, and secure delivery schedules.

We start with the manufacturer — where delivery capability is determined and establish a new, reliable form of collaboration with OEMs, material suppliers, and partners.

We understand service as an open network along the machine — involving everyone who ensures availability.

The result: machines, people, and data work together in real time. Processes are clear, coordination is automated, and value creation is redefined.