AI agents

AI-Agents by Transaction-Network:

Two perspectives. One goal.

At Transaction-Network, artificial intelligence isn’t an add-on feature — it’s built into the core of our platform logic. It ensures that service, maintenance, and information flow are seamlessly connected, not treated as separate processes.

It’s applied on two levels:

- As integrated agents running in the background — detecting patterns and triggering processes.

- As an analytics and prediction system that intelligently links machine data and generates actionable insights.

The goal: efficiency — because it saves time.

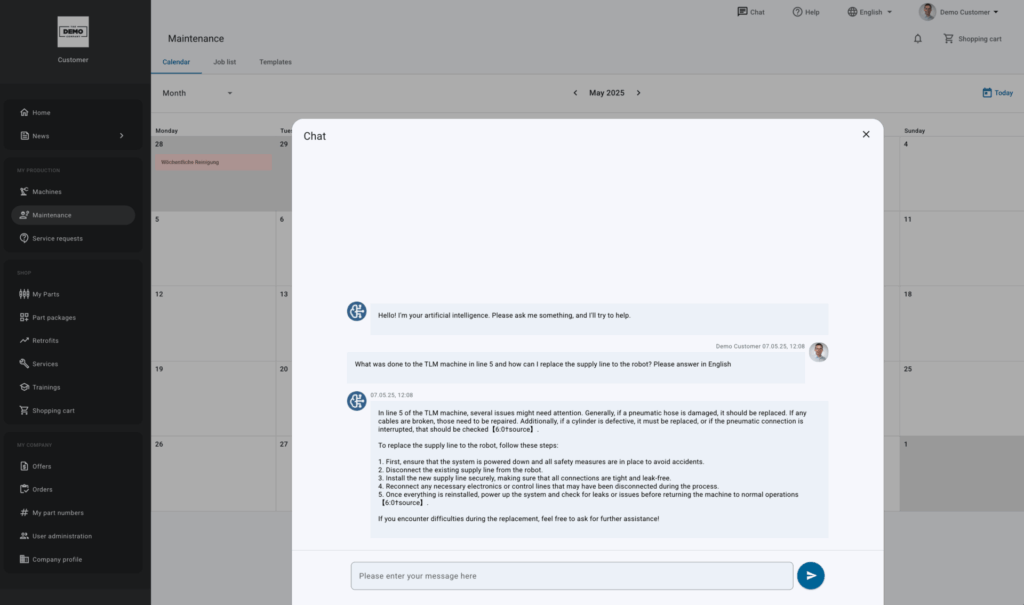

The technical AI agent — your ChatGPT for service

Imagine being able to talk to your machine at any time. Our AI agent makes exactly that possible — not in the traditional sense, but intelligently, using all available information as its foundation.

Bills of materials, CAD data, operating manuals, technical documentation, maintenance history, sensor readings, and current operating data.

What does the agent do?

It answers complex questions in natural language — quickly, precisely, and with full context. No more digging through manuals, searching in Excel, or checking back with engineering.

It answers complex questions in natural language — quickly, precisely, and with full context. No more digging through manuals, searching in Excel, or checking back with engineering.

Want some examples?

- “Which spare parts fit the axis in line 2?”

- “Show me the maintenance manual for the gearbox of the XYZ machine.”

- “What issues occurred last week on machine 4711?”

- “How many times was the valve replaced last year?”

- “Where can I find the CAD model of the gripper?”

How does it work?

The agent searches through the TN data spaces, understands technical relationships, intelligently connects information, and provides answers like an experienced service technician — only faster, more reliably, and always available.

Who is it relevant for?

For everyone responsible for service: maintenance staff, technicians, support teams, and planners. The agent becomes a central access point to knowledge — making your company’s entire technical expertise truly usable.

The answers are context-based, fast, and precise. No one needs to search through Excel or adjust things manually anymore — the system detects, prioritizes, and delegates automatically.

Predictive maintenance with AI — detecting issues before they become critical

The platform analyzes machine data before anyone even asks. Temperature trends, runtimes, faults, usage patterns — everything feeds into a continuous analysis.

Maintenance needs are no longer based on fixed intervals but on actual usage. Spare parts are scheduled before they’re needed, and service operations can be better coordinated and prepared.

For example: when you ask, “Which machines need maintenance this week?”, the system provides a data-driven assessment based on past loads, typical wear patterns, and current sensor data — including actionable recommendations. This way, you know what to do before things become critical.

The system continuously learns — not through separate training, but through real operational experience. Each cycle makes its predictions more accurate. Wear is detected early, maintenance needs arise from actual usage rather than fixed intervals, and spare parts are planned as needed while service operations are automatically prepared.

AI makes us faster and more effective — ensuring stable operations. And the more stable the operations, the more room there is for smart decisions.

3. AI-powered knowledge management

Whether it’s historical maintenance data, common error patterns, or team know-how — the system detects recurring patterns, consolidates distributed information, and presents it in context.

Example: when a known issue is queried, the system provides relevant entries from previous cases — including suggested solutions, affected components, and actions taken. That way, no one has to start from scratch anymore. This is especially helpful when time is critical. New team members get up to speed faster, and decisions are based on proven experience — not assumptions.

Knowledge becomes accessible, usable, and transparent. Not just stored away.

How our AI transforms your day-to-day operations.

The platform thinks along with you. It delivers information before it even becomes a question. It makes suggestions before anyone needs to search. And it supports you without ever getting in the way.

Service becomes more predictable. Communication becomes clearer. Response times become shorter. Management becomes easier — because the system always provides the full context. Maintenance runs more reliably — not because people work harder, but because the system works smarter.

Because machine service has long become too complex to manage reactively. What’s needed are intelligent maintenance solutions that work with machine data — directly, proactively, and seamlessly integrated. This is exactly where our AI for maintenance comes into play — in mechanical engineering, in everyday operations, and in real-world processes.